Berita

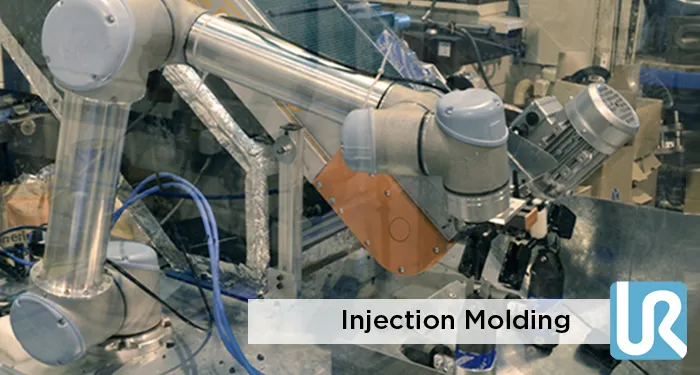

Injection molding by collaborative robot

Gain a rapid and accurate handling of injection molds for prototyping and short-run manufacturing with collaborative robots.

Relieve injection-molding machinery operators from physically demanding, repetitive work and eliminate the risk of injuries. UR industrial robots can be used across all areas of plastic and polymer production, including injection molding applications. They are able to run most applications autonomously, allowing your business to handle molding even when employees have gone home.

For added connectivity and flexibility, Euromap 67 (including the cable connection to the injection-molding machine) is an available option for all UR robots. With Euromap 67 you get user-friendly templates ensuring easy and fast programming as well as communication signals between the robot arm and injection-molding machine.

• Taking a robot out of its safety cage allows unmatched automation flexibility. If the robots come into contact with a person, our patented technology limits the forces at contact. The robots can also be programmed to operate in reduced mode when a human enters the robot’s work area and resume full speed when the person leaves.

• It requires superhuman abilities to dose exactly the same quantity of a fluid constantly. However, the UR robot can maintain consistent pressure at all times. By deploying the robot, you can ensure uniform quality, reduce production costs, and optimize your operation.

• Easy programming and a short average set-up time make Universal Robots robot arms ideal even for small-volume productions, where rearranging large-scale facilities wouldn’t be cost-effective.

• Moving the injection molding robot to new processes is fast and easy, giving you the agility to automate almost any manual task, including those with small batches or fast change-overs. The robot is able to re-use programs for recurrent tasks.

• All Universal Robots robot arms are certified IP-54. They will need protection when working in corrosive liquid environments.

#UNIVERSALROBOTS #JualUNIVERSALROBOTS #UNIVERSALROBOTSIndonesia #DistributorresmiUNIVERSALROBOTS #AgenresmiUNIVERSALROBOTS #CollaborativeRobot #SupplierCollaborativeRobot #JualCollaborativeRobot #DistributorCollaborativeRobot

Lainnya

PT. Surya Sarana Dinamika Visits BBPVP Bekasi for Collaboration on Workforce Competency Enhancement

PT. Surya Sarana Dinamika Visits BBPVP Bekasi for Collaboration on Workforce Competency EnhancementTo improve HR competency

THK in Your Life - In Houses & Buildings

Quake-Absorbing Homes

Certificate Awarding for Asesi and Asesor by LSP Elektroteknika

Thursday, February 27, 2025

THK in Your Life | Medical and Nursing Care

Kursi roda dengan electric lift arms

Rapat Koordinasi Penguatan Link and Match Vokasi Industri

Dinas Perindustrian dan Perdagangan Provinsi Jawa Barat